Solid State Valve Power Supply Project - Circuits

Solid State Valve Power Supply Project - Circuits

All photos copyright John Mills, last updated 27 Dec 2009

All photos copyright John Mills, last updated 27 Dec 2009

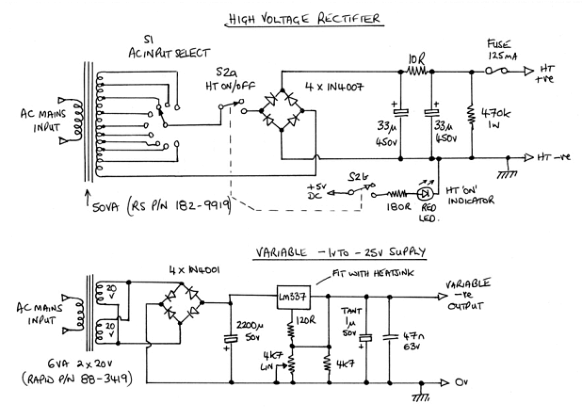

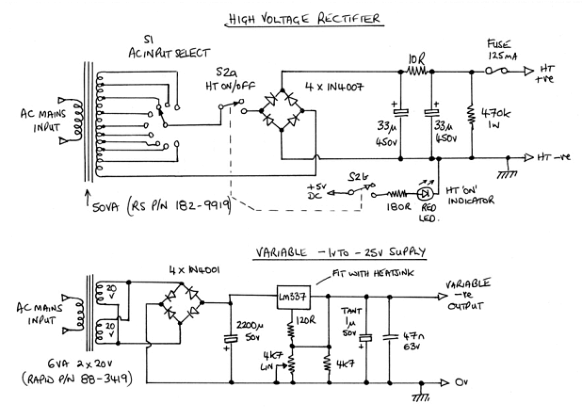

Top circuit shows the HT bridge rectifier fed by the multi-tap secondary. The Electrolytics used here should be capable of a high ripple rating. The 470k 1watt

resistor is used to bleed off any residual voltage in the circuit after switching off.

The bottom circuit is the -1v to -25v power supply for feeding -ve grid bias if needed. It is a standard circuit using a TO220 LM337 fitted to a small heat sink. If

the variable pot is replaced by a 2200 ohm version, the 4k7 in parallel can be omitted.

Top circuit shows the HT bridge rectifier fed by the multi-tap secondary. The Electrolytics used here should be capable of a high ripple rating. The 470k 1watt

resistor is used to bleed off any residual voltage in the circuit after switching off.

The bottom circuit is the -1v to -25v power supply for feeding -ve grid bias if needed. It is a standard circuit using a TO220 LM337 fitted to a small heat sink. If

the variable pot is replaced by a 2200 ohm version, the 4k7 in parallel can be omitted.

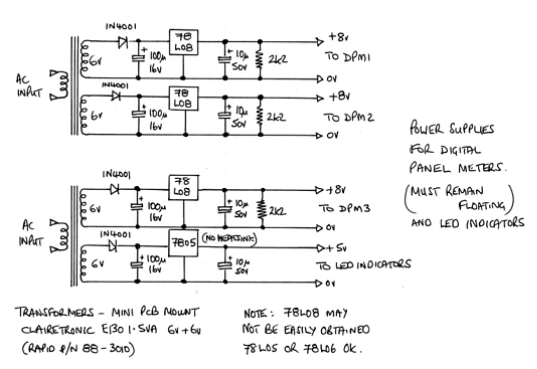

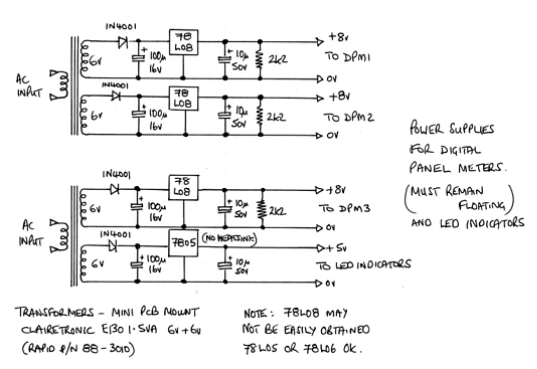

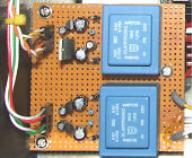

Since the digital panel meters (DPM) have to have their

supplies isolated from ground, the simplest solution

was to make two smaller power supplies using PCB

mounting transformers. The two front panel indicators

are fed from the 5v supply. The DPM's were specified

at 5v - 9v dc supply, I chose 8v simply because I had

these regulators available. Nowadays it is likely that

only 5v or 6v versions are readily available. The 10uF

capacitors can all be 16v versions, again it was what I

had.

Since the digital panel meters (DPM) have to have their

supplies isolated from ground, the simplest solution

was to make two smaller power supplies using PCB

mounting transformers. The two front panel indicators

are fed from the 5v supply. The DPM's were specified

at 5v - 9v dc supply, I chose 8v simply because I had

these regulators available. Nowadays it is likely that

only 5v or 6v versions are readily available. The 10uF

capacitors can all be 16v versions, again it was what I

had.

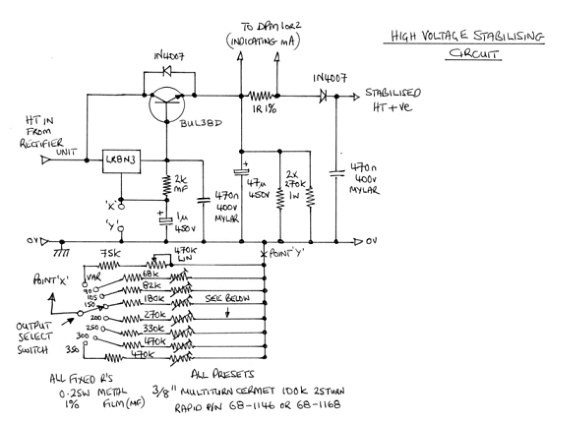

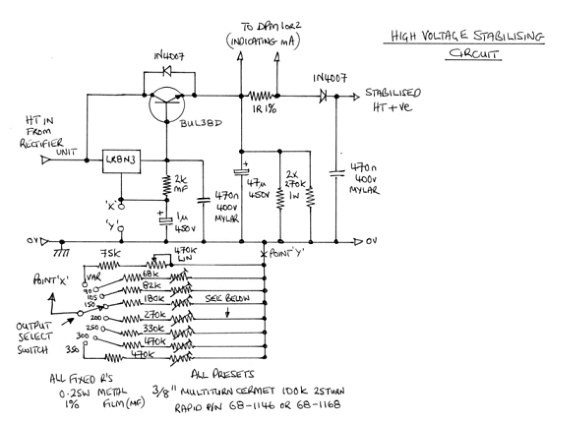

This is one channel of the regulator circuit. The other is identical, although

if you wish the preset voltages could be different. The selector switch

offers a variable (45v - 350v) option, with the preset positions giving 90v,

105v, 150v, 200v, 250v, 300v & 350v options. These are all set with multi

turn miniature trim pots to give the correct output voltage under a 100mA

load. The output will rise slightly for lower loads, but is still within 5v of the

target setting. The 1N4007 across the Collector/Emitter of the BUL38D is

actually redundant as this device has an internal diode built in. I left it in

as a backup. The other 1N4007 protects the devices against any external

high voltage being applied to the output terminals when the unit is

powered off. The BUL38D devices are attached to an external heat sink. I

used an Aavid type 6W1, available from Rapid Electronics in the UK. P/N

36-0125.

This is one channel of the regulator circuit. The other is identical, although

if you wish the preset voltages could be different. The selector switch

offers a variable (45v - 350v) option, with the preset positions giving 90v,

105v, 150v, 200v, 250v, 300v & 350v options. These are all set with multi

turn miniature trim pots to give the correct output voltage under a 100mA

load. The output will rise slightly for lower loads, but is still within 5v of the

target setting. The 1N4007 across the Collector/Emitter of the BUL38D is

actually redundant as this device has an internal diode built in. I left it in

as a backup. The other 1N4007 protects the devices against any external

high voltage being applied to the output terminals when the unit is

powered off. The BUL38D devices are attached to an external heat sink. I

used an Aavid type 6W1, available from Rapid Electronics in the UK. P/N

36-0125.

Solid State Valve Power Supply Project - Circuits

Solid State Valve Power Supply Project - Circuits

All photos copyright John Mills, last updated 27 Dec 2009

All photos copyright John Mills, last updated 27 Dec 2009

Top circuit shows the HT bridge rectifier fed by the multi-tap secondary. The Electrolytics used here should be capable of a high ripple rating. The 470k 1watt

resistor is used to bleed off any residual voltage in the circuit after switching off.

The bottom circuit is the -1v to -25v power supply for feeding -ve grid bias if needed. It is a standard circuit using a TO220 LM337 fitted to a small heat sink. If

the variable pot is replaced by a 2200 ohm version, the 4k7 in parallel can be omitted.

Top circuit shows the HT bridge rectifier fed by the multi-tap secondary. The Electrolytics used here should be capable of a high ripple rating. The 470k 1watt

resistor is used to bleed off any residual voltage in the circuit after switching off.

The bottom circuit is the -1v to -25v power supply for feeding -ve grid bias if needed. It is a standard circuit using a TO220 LM337 fitted to a small heat sink. If

the variable pot is replaced by a 2200 ohm version, the 4k7 in parallel can be omitted.

Since the digital panel meters (DPM) have to have their

supplies isolated from ground, the simplest solution

was to make two smaller power supplies using PCB

mounting transformers. The two front panel indicators

are fed from the 5v supply. The DPM's were specified

at 5v - 9v dc supply, I chose 8v simply because I had

these regulators available. Nowadays it is likely that

only 5v or 6v versions are readily available. The 10uF

capacitors can all be 16v versions, again it was what I

had.

Since the digital panel meters (DPM) have to have their

supplies isolated from ground, the simplest solution

was to make two smaller power supplies using PCB

mounting transformers. The two front panel indicators

are fed from the 5v supply. The DPM's were specified

at 5v - 9v dc supply, I chose 8v simply because I had

these regulators available. Nowadays it is likely that

only 5v or 6v versions are readily available. The 10uF

capacitors can all be 16v versions, again it was what I

had.

This is one channel of the regulator circuit. The other is identical, although

if you wish the preset voltages could be different. The selector switch

offers a variable (45v - 350v) option, with the preset positions giving 90v,

105v, 150v, 200v, 250v, 300v & 350v options. These are all set with multi

turn miniature trim pots to give the correct output voltage under a 100mA

load. The output will rise slightly for lower loads, but is still within 5v of the

target setting. The 1N4007 across the Collector/Emitter of the BUL38D is

actually redundant as this device has an internal diode built in. I left it in

as a backup. The other 1N4007 protects the devices against any external

high voltage being applied to the output terminals when the unit is

powered off. The BUL38D devices are attached to an external heat sink. I

used an Aavid type 6W1, available from Rapid Electronics in the UK. P/N

36-0125.

This is one channel of the regulator circuit. The other is identical, although

if you wish the preset voltages could be different. The selector switch

offers a variable (45v - 350v) option, with the preset positions giving 90v,

105v, 150v, 200v, 250v, 300v & 350v options. These are all set with multi

turn miniature trim pots to give the correct output voltage under a 100mA

load. The output will rise slightly for lower loads, but is still within 5v of the

target setting. The 1N4007 across the Collector/Emitter of the BUL38D is

actually redundant as this device has an internal diode built in. I left it in

as a backup. The other 1N4007 protects the devices against any external

high voltage being applied to the output terminals when the unit is

powered off. The BUL38D devices are attached to an external heat sink. I

used an Aavid type 6W1, available from Rapid Electronics in the UK. P/N

36-0125.